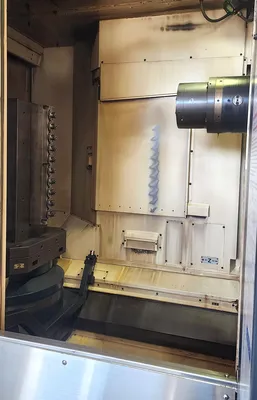

2018 Makino A61NX Pro 6 CNC, installed in 2020. Features 19.7" pallets, full 4th axis, Probe system, 1000 PSI Through Spindle Coolant, 14,000 RPM spindle, and 60 position ATC. Low usage; cutting time 2,200 hrs. Includes Renishaw probe, through spindle coolant, and more.

MAKINO PRO 6 CNC

FULL 4TH AXIS (CONTOURING) ON PALLET INDEX

30 HP CONTINUOUS/ 50 HP DUTY RATED

PQI / RENISHAW OM-400 & NC4S PROBE SYSTEM COMBO

- RENISHAW COMPACT OMP400 RENGAGETM HIGH ACCURACEY OPTICAL STRAIN GAUGE PROBE AMS

- NC4S NON-CONTACT LASER ATLM WITH CUSTOM BRACKETS

THROUGH SPINDLE COOLANT PREPPED

CHIPBLASTER 1000 PSI HV-40 MULTIPLE PRESSURE THROUGH SPINDLE COOLANT SYSTEM

SECONDARY FILTER FOR THROUGH SPINDLE COOLANT

CHIP CONVEYOR LSW880

1G FEED AXIS ACCELERATION X/Y (1G/1G)

60 POSITION ATC

APC DOOR INTERLOCK

(8) COOLANT NOZZLES POSITIONED AROUND SPINDLE FACE

OVERHEAD SHOWER COOLANT (14 NOZZLES)

AIR DRYER

VISION B.T.S (BROKEN TOOL SENSOR) MOUNTED IN ATC MAGAZINE

FIRE EXTINGUISHER INTERFACE

LINEAR INTERPOLOATION TYPE POSITIONING

HELICAL INTERPOLATION (G02,G03)

2 GB PROGRAM MEMORY (ADDITIONAL 1 GB MEMORY FOR IMAGE AND DATA FILES)

TOOL OFFSET - 400 PAIRS

WORKPIECE COORDINATE SYSTEM - 54 PAIRS

OPTIONAL BLOCK SKIP - 9 TOTAL

CUSTOM MACRO COMMON VARIABLES - 1100

COORDINATE SYSTEM ROTATION

HIGH SPEED SKIP

ADAPTIVE CONTROL FUNCTION

GI CONTRO (MOTION CONTROL SYSTEM W/VARIOUS FUNCTIONS)

TRANSFORMER

MACHINE IS WIRED FOR 460V

COST FOR ABOVE EQUIPPED MACHINE WHEN PURCHASED NEW IN 2020: $448,380

NOTES:

* MACHINE WAS SOLD AND INSTALLED IN 2020. PURCHASED FOR 737 MAX PROJECT AND NEVER CUT A PART FOR IT BY TIME JOB WAS CANCELLED. CYCLED THROUGH BI-WEEKLY. SELDOM USED.

ENERGIZED TIME: 13,908 HOURS

OPERATION TIME: 3,229 HOURS

CUTTING TIME: 2,200 HOURS

SPINDLE SPIN TIME: 3,185 HOURS

*** MACHINE IS AVAILABLE FOR IMMEDIATE INSPECTION AND PURCHASE.

We use cookies to improve your experience. Privacy Policy.